Repairing Industrial Refrigeration Repair Service: Strategies for Quick and Effective Fixes

In the world of commercial refrigeration, the requirement for swift and exact troubleshooting strategies is vital. When a refrigeration unit breakdowns, the repercussions can be pricey and disruptive to company operations. Recognizing the common concerns that torment business refrigeration systems and having a toolkit of diagnostic strategies available can make all the distinction in quickly recognizing and correcting problems. As we navigate via the ins and outs of troubleshooting industrial refrigeration repair work, we will certainly discover the vital methods for dealing with concerns efficiently, making certain that services can preserve optimal cooling efficiency and lessen downtime.

Common Industrial Refrigeration Problems

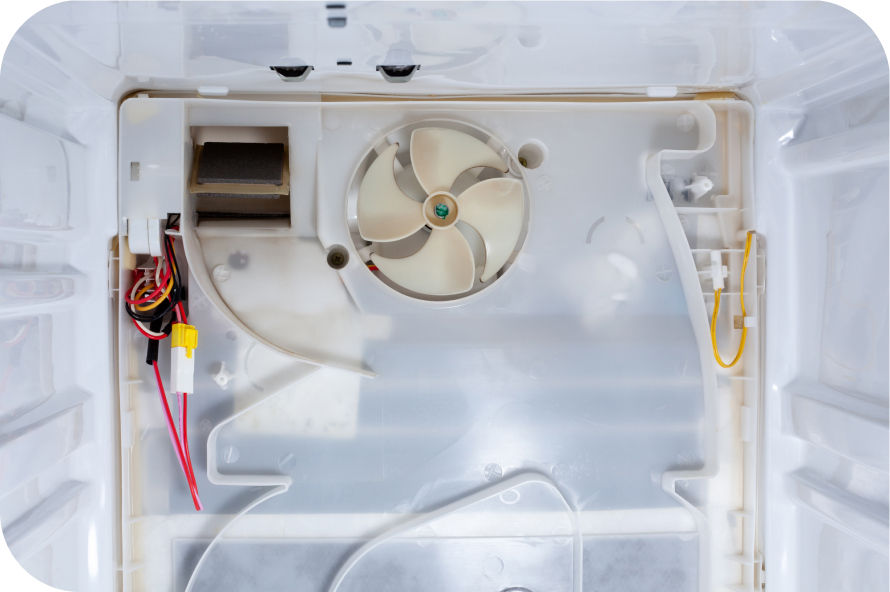

Business refrigeration systems commonly experience a variety of operational problems that can interrupt their performance and efficiency. One common concern is inappropriate temperature level control, which can lead to food perishing and waste if not promptly dealt with. This problem may originate from concerns with the thermostat, evaporator follower, or condenser coils, calling for detailed inspection to pinpoint the source. Another common issue is inadequate airflow, typically brought on by obstructions in the vents or a malfunctioning fan. Poor air movement can lead to temperature incongruities within the fridge or freezer, impacting the high quality and safety of saved items.

Moreover, refrigerant leakages pose a substantial worry as they not only influence the cooling capability of the system yet additionally contribute to ecological injury. Regular cleaning and upkeep can help prevent this concern and prolong the lifespan of the refrigeration system.

Analysis Tools and Strategies

Effective troubleshooting of commercial refrigeration systems counts heavily on making use of specialized diagnostic devices and strategies to identify and fix underlying issues effectively - commercial refrigeration repair. In addition, leak discovery devices like digital leak detectors or ultraviolet dye packages are essential for situating cooling agent leaks that can lead to system inadequacies.

Data loggers can be utilized to keep track of system efficiency over time and discover trends that may suggest recurring troubles. By incorporating these analysis tools and methods, technicians can properly troubleshoot business refrigeration systems and give fast and specific repairs, minimizing downtime and making certain ideal system efficiency.

Quick Repairs for Refrigeration Problems

When faced with refrigeration problems, service technicians can implement fast repairs to resolve common issues promptly and efficiently. If the refrigeration device is not cooling down properly, inspecting and adjusting the thermostat this contact form setups may supply a quick option prior to more extensive troubleshooting is needed. By carrying out these fast fixes, professionals can resolve typical refrigeration troubles efficiently and keep industrial refrigeration systems running smoothly.

Preventative Maintenance Tips

Implementing an aggressive maintenance timetable is crucial for guaranteeing the long life and optimum efficiency of business refrigeration systems. Regular maintenance not just aids prevent expensive break downs yet likewise makes certain that the equipment runs successfully, saving energy and minimizing total operating expense. Below are some preventative maintenance ideas to maintain commercial refrigeration systems running efficiently:

Examine and Replace Filters: Dirty filters can restrict commercial refrigerator repair air movement, making the system job harder and possibly triggering damage. Inspect and replace filters on a regular basis to stop issues.

Inspect Seals and Gaskets: Dripping seals and gaskets can bring about temperature level variations and power waste. Replacing and evaluating damaged seals can assist maintain regular temperature levels.

Expert Assistance and Services

To maintain the optimal performance attained with normal preventative upkeep, looking for specialist support and solutions for business refrigeration systems is essential. Specialist specialists have the expertise and specialized expertise required to identify and attend to complex issues efficiently. When encountering tough refrigeration issues, counting on expert support can save both money and time in the long run.

Professional solutions offer benefits such as access to advanced devices and equipment, guaranteeing that repair work are accomplished effectively. Additionally, technicians are trained to adhere to industry guidelines and safety and security criteria, decreasing the danger of accidents and ensuring conformity with lawful requirements.

Verdict

In conclusion, troubleshooting business refrigeration fixing calls for a methodical method to determining common issues, utilizing diagnostic tools and techniques, implementing fast fixes, and prioritizing preventative maintenance. Expert assistance and solutions might be essential for even more facility issues - commercial refrigeration repair. By adhering to these methods, companies can guarantee their refrigeration systems operate successfully and properly, minimizing downtime and potential losses

Recognizing the common issues that afflict industrial refrigeration systems and having a toolkit of diagnostic methods at your disposal can make all the distinction in quickly determining and fixing troubles.Efficient troubleshooting of industrial refrigeration systems relies greatly on utilizing specialized diagnostic devices and techniques to identify and settle underlying concerns efficiently. By incorporating these analysis devices and techniques, technicians can successfully troubleshoot industrial refrigeration systems and provide accurate and fast fixings, lessening downtime and making sure optimal system efficiency.

By executing these fast repairs, technicians can resolve usual refrigeration troubles successfully and maintain business refrigeration systems running smoothly.

Furthermore, specialist support can assist extend the lifespan of industrial refrigeration systems by identifying prospective concerns prior to they intensify.